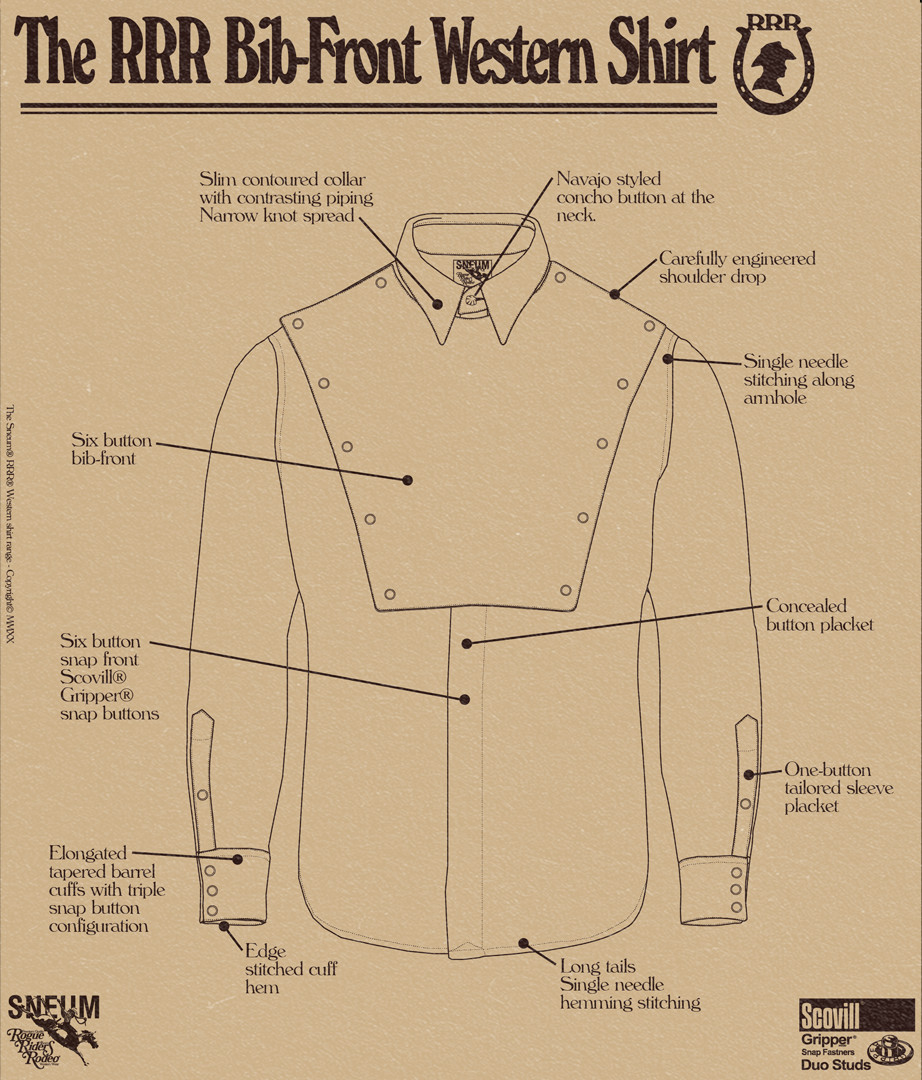

Bib-front western shirt in black Tencel

€200.00

- Scovill® contrasting round snap buttons

- Piped edges along bib front

- Concealed buttons on front placket

- Long sleeves with snapped barrel cuffs

- Long tails

- Edge stitching using fine thread and extra high Stitching Per Inch (SPI)

- Tencel® (organic) in a 210GSM twill weave

- Long sleeves with snapped barrel cuffs

READ MORE

COLOR:

WEAR WITH

-

Single point western shirt in black pique

€1350210301-060100

-

Ulster military overcoat

€7000120101-100303

-

Smile pocket western shirt

€1900210303-030100

-

Sawtooth western shirt in denim with red seams

€1600310302-040301

OTHER SUGGESTIONS

-

Bolero western jacket in wool

€4700320306-260100

-

4-piece ranger belt in black suede and leather

€1500130303-210100

-

Western down vest with single-piece leather yoke

€4000120201-080100

-

Civil war cavalry trucker cap in black

€550130302-110100

-

4-piece ranger belt in straight version

€1500130306-280100

The range of shirts have all been done with the scope to enhance all quintessential design elements of the western shirt such as the signature pointed yokes on the front and on the back, longer tails, duel chest pockets with pointed flaps, pearl-snap closures down the front placket, and at the pearl-snapped cuffs.

All such design elements were conceived for a utilitarian purpose. A lonesome rider out on the range wouldn’t have to worry about carrying needle and thread to replace a button; the flaps on his pockets kept his tobacco tin from bouncing out while he rode; the yokes, with their double fold, made his shirt durable; the tighter fit prevented his shirt from getting caught on saddle horns and barbed wire; and the extra-long tails stayed tucked into jeans.

"done with the scope to enhance all quintessential design elements of the western shirt"

"Western shirt pockets are like the grill on a car: they define the western shirt as much as any other element, or more"

The bib shirt tracks its origin back to mid-19th firefighters on both sides of the Atlantic, as the distinctive “shield” front provided extra warmth around the chest, acting as a windbreaker to block cold winter winds.

When Isaac Singer began mass producing sewing machines in 1856, it suddenly became possible to mass produce clothing as well. The factory-made shirt came along just in time for the American Civil War, when the northern and southern armies had an urgent need for millions of mass produced uniforms. Bib front shirts became a popular uniform choice in both armies as the bib not only gave a soldier extra protection against the elements, but it also served as an easy to access place for a soldier to store a tobacco pouch, pictures of loved ones, letters from home, or a light lunch, leaving his hands free for his knapsack and weapon.

After the war, many soldiers returned home only to join the United States largest westward migration and their bib front shirts went with them. Since they were made of fine gabardine wool, they lasted forever. (The Union made everything out of wool, including the soldiers’ underwear, hence the name “Union suit.”) There was little need for formal attire in the wild west, and the bib front shirt quickly became a standard western garment and trademark of the American cowboy.

Hollywood’s Golden Age Westerns truly popularized the bib shirt. John Wayne wore bib shirts in numerous films, including 1939’s Stagecoach, 1947’s Angel and the Badman, 1948’s Red River and 1956’s The Searchers.

Why we use Scovill® Gripper®

The Sneum RRR range of western shirts are all made using original Scovill® Gripper® snap buttons. Founded more than 200 years ago in Waterbury, Connecticut. USA,

Scovill® is a pioneer within snap buttons and accredited for being the first to apply snap buttons to western shirts back the mid 1940s. Their groundbreaking methods has made them into an industry icon synonymous with highest quality, durability and style.

This is not just a snap button. This is a piece of history.

On TENCEL™

We chose to introduce TENCEL™ in our range of western shirts for two main reasons:

Secondly TENCEL™ is one of the most environmentally friendly fabrics on the market. It is made from cellulose in wood pulp, which is harvested from tree-farmed eucalyptus trees. Cellulose is the natural polymer that makes up the living cells of all vegetation. The tree farms have been established on land unsuitable for food crops or grazing—no old growth forests, genetic manipulation, irrigation, or pesticides are used.

The fiber is produced via an advanced ‘closed loop’ solvent spinning process, with minimal impact on the environment and economical use of energy and water. The solvent used in the process is toxic but 99% is recovered and continually recycled. The process received the European Award for the Environment from the EU.

Key properties:

- Comfortable: Similar to rayon in feel, Tencel is soft, breathable, lightweight and comfortable.

- Lasting: Shrink-resistant, durable and easy to care for, Tencel is an exceptionally strong fiber, both wet and dry.

- Color Rich: Tencel was created with color in mind, because of the fibers’ high absorbency. The fabrics can be dyed to high quality standards.

- Easy to Maintain: Tencel garments are easy to pack, resist wrinkling and dry quickly. Most are machine washable, although different garment constructions may have specific cleaning requirements.

- Natural: Tencel is made from the natural cellulose found in wood pulp. The fiber is economical in its use of energy and natural resources, and is fully biodegradable

SNEUM

Copenhagen based

menswear brand

proposing a

Scandinavian take

on the Americana

aesthetics