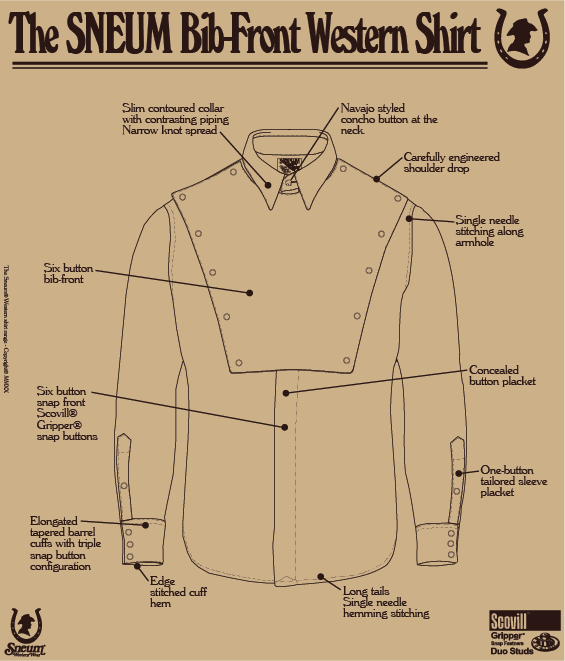

The range of shirts have all been done with the scope to enhance all quintessential design elements of the western shirt such as the signature pointed yokes on the front and on the back, longer tails, duel chest pockets with pointed flaps, pearl-snap closures down the front placket, and at the pearl-snapped cuffs.

All such design elements were conceived for a utilitarian purpose. A lonesome rider out on the range wouldn’t have to worry about carrying needle and thread to replace a button; the flaps on his pockets kept his tobacco tin from bouncing out while he rode; the yokes, with their double fold, made his shirt durable; the tighter fit prevented his shirt from getting caught on saddle horns and barbed wire; and the extra-long tails stayed tucked into jeans.